News - Construction News

From Paddy to Panel: Harnessing Rice Husk Waste for Sustainable Building Insulation

In the construction industry, thermal insulation remains a critical challenge, especially as energy efficiency and sustainability become ever more important. Traditional insulation systems often rely on petrochemical-based materials, which, while effective, carry a high carbon footprint and can pose a fire risk. Even natural alternatives like wool or cork have limitations, such as resource scarcity or energy-intensive processing.

Existing technologies for building envelope insulation typically involve the on-site installation of panels made from synthetic materials, fixed with adhesives and mechanical fasteners. These methods can be labour-intensive, disruptive to building occupants, and come with a significant environmental impact. Whilst prefabricated systems have addressed some of these issues, many still rely on high-carbon materials or adhesives, limiting their sustainability benefits.

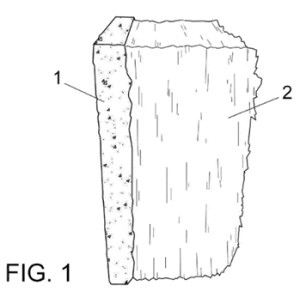

European Patent EP4471221B1, granted to AIDIMME in November 2025, describes a method of prefabricating a novel cladding element that uses rice husk waste – a by-product of rice production – as its core insulating material. The invention centres on the production of a multilayer panel formed of an insulating layer (2), which is fixed to a layer of mortar (1). The layer of mortar is made with recycled aggregate comprising construction and demolition waste. The insulating layer is formed of rice husk agglomerated with an adhesive and treated with an anti-fungal product. Notably, the rice husk requires no energy-intensive pre-treatment, and the mortar and husk layers are bonded during the curing process, without additional adhesives.

Commercially, this patented technology offers several advantages. Prefabrication reduces installation time and disruption, whilst the use of recycled and renewable materials lowers both environmental impact and carbon footprint. The system also contributes to waste management by repurposing rice husk and construction debris, aligning with circular economy principles. For building owners and contractors, improved thermal and acoustic performance, durability, and ease of installation translate into long-term cost savings and enhanced comfort for occupants.

Even in an established field of innovation, such as insulation panels, this patented technology demonstrates that there is still room for something new – especially when sustainability is at stake. By securing patent protection, AIDIMME benefits from a 20-year period of commercial exclusivity, and an opportunity to position itself at the forefront of eco-friendly building solutions.

Chris Hambley is a senior associate and patent attorney in the Advanced Engineering group at European IP firm, Withers & Rogers.

Related Articles

More News

- Government unveils water industry overhaul

5 Feb 26

The UK Government has announced an unprecedented overhaul of the national water system.

- New homes for Wychavon Town

4 Feb 26

Homes England and Summix agree outline planning for the new settlement of Wychavon Town.

- Bridgwater Tidal Barrier Scheme

3 Feb 26

The Bridgwater Tidal Barrier scheme, a major infrastructure initiative led by the Environment Agency, has